Manufactured in carbon and stainless steel

We manufacture in both carbon steel and stainless steel grades 304 and 316. Our materials are sourced from European steel mills which have the supporting test certificates ensuring the correct material grades are supplied. This complies fully with our ISO 9001:2015 quality audit requirements.

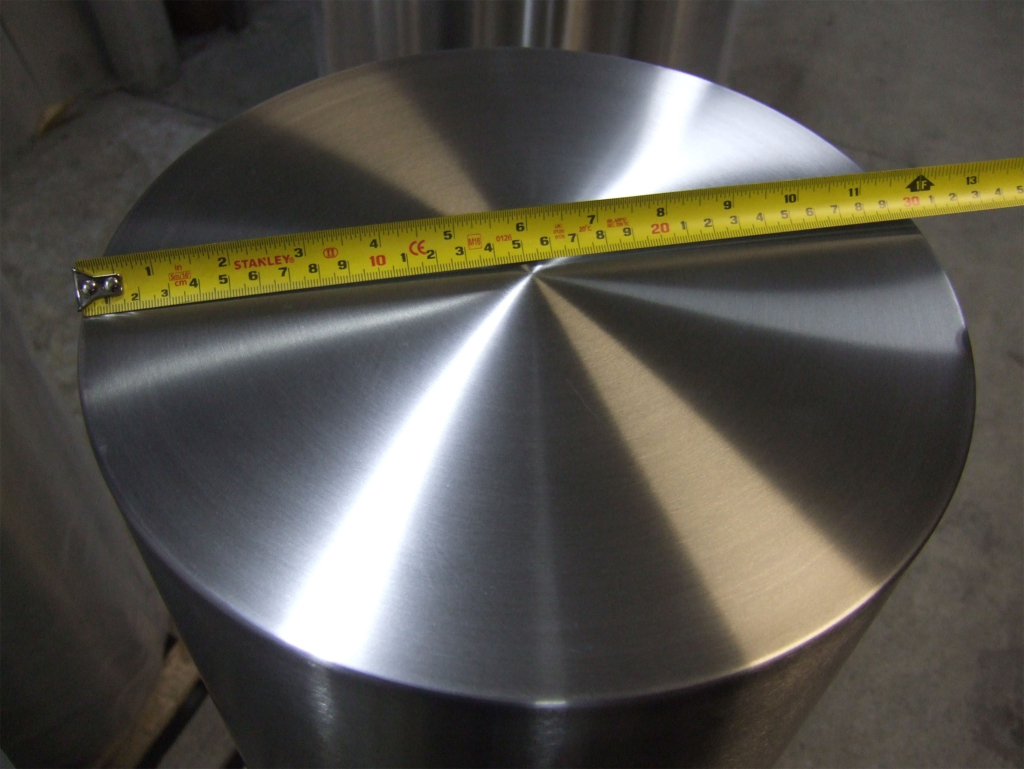

Stainless steel polishing

All stainless steel polishing is carried out in house on modern state of the art machinery utilising the very latest abrasive technology. We are fortunate to act as a manufacturing test facility for Europe’s leading abrasives manufacturer, this ensures that we always operate with the most advanced abrasives which gives us a competitive advantage in all aspects of stainless steel finishing.

Stainless steel surface finish Ra testing

During both production and abrasive trials, surface finish is regularly measured and recorded providing consistent quality with the specified Ra reading obtained. This ensures maximum corrosion resistance to all stainless steel products.

Shot blasting steel products

We operate a large capacity automatic wheelabrator machine which shot blasts steel products leaving a clean, scale free finish ideally suited to further processing. Products requiring galvanizing are subcontracted and this process is quality assured to BS ISO EN1461.

Rilsan® Nylon dip coating specialists

We are specialists in Rilsan® Nylon dip coating. For further information on this remarkable material please see the dedicated information on our website.